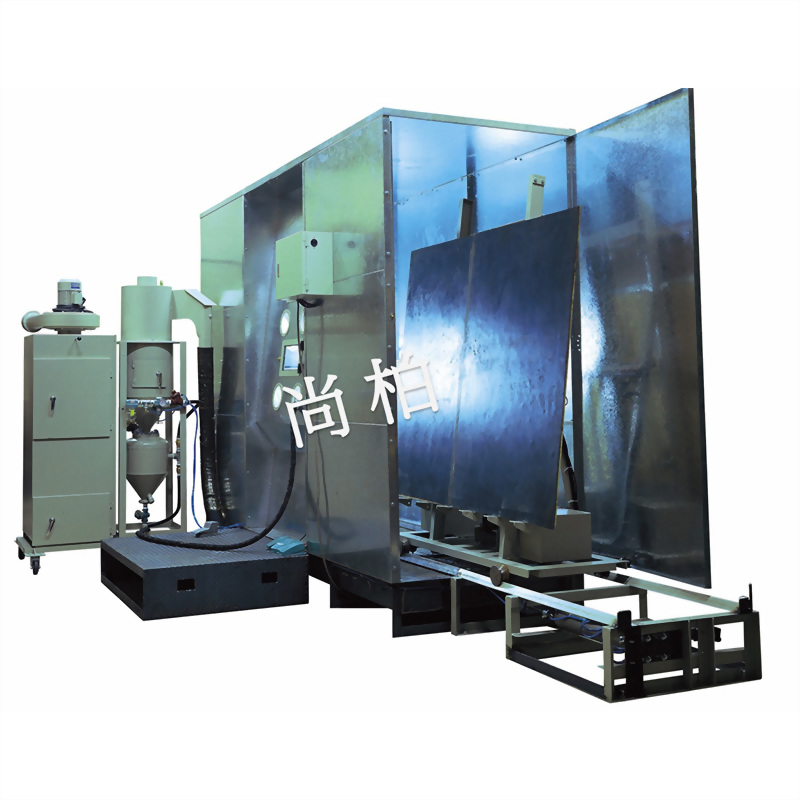

TM-BR Walk-in Blasting Chamber

Blasting chamber specific for glass carving industry:

1. Equipped with an electric cart-delivering device. The operator may proceed blasting through the hand-stretching hold outside of the cabin.

2. The cart cab be driven to the blasting chamber to place/retrieve workpieces, which can be moved up/down/right/left, saving the time necessary for moving, delivery and stop for enhancing work efficiency and reducing personnel pollution.

3. Sand material is automatically collected in the collection bucket through the ground scraper and then recycled in the storage tank via the cyclone or bucket device without sweeping the sand. Saving time and manpower in a great proportion in sand recycle and thereby enhancing the production capability.

Features:

1. Scraping dust-sweeping devices without digging up the foundation and with little restriction for space.

2. Built-in anti-dust and waterproof fluorescent lamps lighting system.

3. Optional for two types of sand recycling devices: cyclone recycle and bucket recycle.

4. Equipped with a dust-collecting system to avoid powder pollution and to increase visibility.

Application:

Blasting of plate objects and large-sized workpieces such as stone, glass and iron sheet.

A blasting

chamber used for ordinary glass consists of the following components

1.Dust-collector

6.Hoist platform

11.nozzle

2.Blasting cabinet (open)

7.Hand-stretching iron ring

12.Blasting pipe

3.Air compressor

8.hand-stretching glove

13.Blasting chamber

4.Freezing drier

9.Transient-control system

14.blasting-proof rubber

5.Automatic sand recycling system

10.Sand

15.Blasting glove