SHANG-PO SANDER CO., LTD. was established in 1975. It produces manual sandblasting machines, wet sandblasting machines and a variety of high-tech automatic sandblasting machines. It is the largest producer of sandblasting power sandblasting machines in Taiwan. manufacturer. We also introduced a variety of special sandblasting models, parts and nozzles from Europe and the United States that could not be produced in China, and introduced new sandblasting technologies.

SHANG-PO sandblasting machines are exported to the United States, Japan, China, South Korea, Thailand, Malaysia, the Philippines, Indonesia, Pakistan, India and Vietnam and other countries. And set up sandblasting and grinding-sweeping sandblasting machine manufacturing plants and professional valet sandblasting processing plants in China to supply the Chinese market and guarantee the sandblasting machines exported from Taiwan to China.

SHANG-PO is constantly committed to improving and developing various types of sandblasting machines, and can also design customized models according to customer products and needs, such as: customized machine design for special workpieces, automatic product production and robotic arm automation, etc.; The components of the table are selected from the highest quality parts, and matched with suitable and high-quality parts according to the special operation requirements.

For sandblasting abrasive grains, SHANG-PO imports and distributes all kinds of sandblasting abrasive grains, such as plastic grains, emery, alumina, glass beads, rounded steel gravel, alloy microbeads, ceramic beads, etc.

The sand blasting machines produced by SHANG-PO in Taiwan are equipped with advanced cyclone separators and super dust collectors, which can reduce pollution. Its design fully grasps the current demands of environmental protection and energy conservation.

Business items:

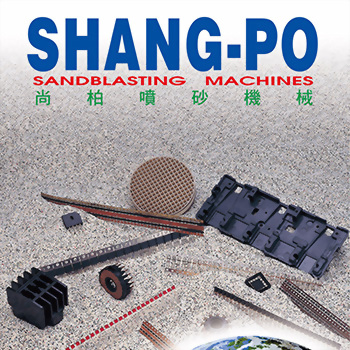

(1) Professional design and manufacture of various types of sandblasting machines.

(2) Professional design of IC wafer surface sandblasting, diode chip sandblasting, cutting and electronic parts packaging industry-specific sandblasting machine, clean room special sandblasting machine.

(3) The peripheral equipment parts of various sandblasting machines and dust collectors are available from stock: spray guns, nozzles (boron carbide, tungsten steel, ceramics) and other vulnerable parts.

(4) General sandblasting materials available from stock: white alumina and micropowder, brown alumina, gold steel sand, silicon carbide, glass beads, plastic particles, steel balls, steel gravel, stainless steel gravel (beads), stainless steel segment sand, zirconium sand, etc. .